What are the key points for selection of industrial motherboards?

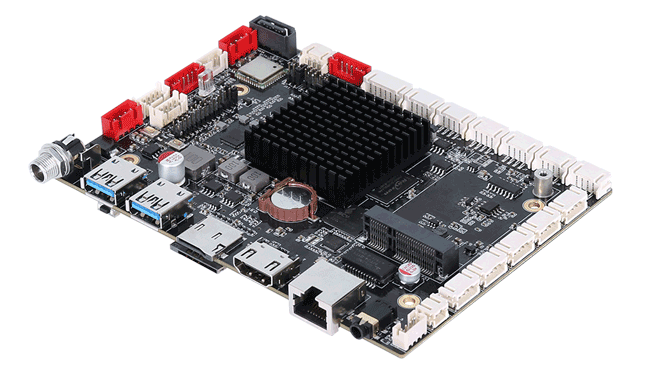

Industrial-grade computer motherboards, also known as industrial motherboards or industrial control motherboards, are industrial-grade printed circuit boards (PCBs) located inside computer enclosures. They primarily serve as a platform that provides connectivity and expandability for most computer hardware components. These motherboards typically feature higher reliability, a wider operating temperature range, more expansion interfaces, and stricter quality control to meet the requirements of industrial environments.

Key Features of Industrial Motherboards:

- Multifunctionality: Typically equipped with a variety of interfaces and slots, supporting multiple peripheral devices and expansion cards.

- Rich I/O Options: Input/output interfaces can meet the requirements of various industrial applications.

- Diverse Sizes: Available in form factors such as ATX, Micro-ATX, and Mini-ITX, to adapt to different industrial application environments.

- Flexible Customization: Can be customized according to customers’ specific needs.

- Compatibility with Multiple Operating Systems: Supports operating systems including Windows, Linux, and Unix.

- Diverse CPU Socket Types: Compatible with various CPU models, such as LGA1200, LGA1151, LGA1150, Intel ElkhartLake J/N series, and Intel Gemini Lake series.

Main Applications of Industrial Motherboards:

- Monitoring and Controlling Various Physical Parameters and Signals: Such as temperature, humidity, pressure, speed, and position. It enables real-time acquisition and processing of various physical information for system control and adjustment.

- Human-Machine Interaction (HMI): Integrates with HMI devices (e.g., touchscreens, keyboards, mice) to allow users to conveniently operate and monitor industrial systems—including setting parameters, modifying configurations, and issuing commands—thereby improving system reliability and operability.

- Remote Monitoring and Control: Connects to communication networks to realize data transmission and communication with other devices or computers, enabling distributed control and management. Remote monitoring and control greatly enhance the convenience and work efficiency of engineers and administrators, while facilitating centralized system management and remote maintenance.

- Data Storage and Processing: Performs data storage and processing to meet the needs of industrial applications.

In addition, industrial motherboards also support a variety of communication protocols and bus interfaces, such as RS232, RS485, USB, and Ethernet, to meet different communication requirements.

Key Points for Customization of Industrial Motherboards

Industrial motherboards have a wide range of applications and operate in complex environments, so users have high requirements for their functionality, compatibility, and reliability. The key points for industrial motherboard customization are as follows:

- Form Factor & Architecture

Industrial motherboards come in various form factors, including 3.5-inch, 5.25-inch, ATX, Micro-ATX, half-length cards, and full-length cards. Classified by chip type, they include X86 architecture, ARM architecture, etc. These options can meet the requirements of different operating environments and performance needs.

- Components

The components of industrial motherboards differ from those used in commercial motherboards. They need to meet the demands of industrial scenarios such as high-temperature resistance and moisture resistance. When selecting components for industrial motherboards, the components must undergo long-term and rigorous verification to ensure the product’s high reliability under complex conditions.

- Interface Design

When designing interfaces for industrial motherboards, customization based on the application scenario or integration of standard interfaces is required to adapt to external devices. Common interfaces include COM ports, USB ports, VGA ports, HDMI ports, and LPT ports. In addition to supporting PCI slots, they can also accommodate PCIe, Mini PCIe, and mSATA slots. Built-in GPIO buses enable GPI (General Purpose Input) and GPO (General Purpose Output) functions. Moreover, industrial half-length and full-length cards can work with backplanes to support multiple PCI, PCIe, and Mini PCIe expansions, offering enhanced expandability. Furthermore, due to the complex operating scenarios of industrial motherboards, they must be designed with surge protection and anti-static capabilities.

- Product Lifecycle

Stability is a prerequisite for industrial applications. Industrial motherboard manufacturers are required to provide a long and stable supply cycle to ensure the stability of the entire equipment or system.

- Protection Functions

Through special design, industrial motherboards can trigger an automatic watchdog restart in the event of abnormalities such as system crashes, ensuring the system meets high stability requirements in harsh environments.

Key Points for Selecting Industrial Motherboards

Manufacturing Process

When selecting an industrial motherboard, the first factor to evaluate is its manufacturing process. The assessment of an industrial motherboard’s manufacturing process involves five key aspects:

- Check the sophistication of the motherboard’s craftsmanship, such as whether the circuit board is a multi-layer board (preferably 6 layers or more), whether the solder joints (including wave soldering joints) are neat and clean, and whether the circuit traces are concise and clear;

- Inspect the motherboard’s components;

- Assess if the design structure meets future upgrade and installation needs, if the layout is reasonable, and if it facilitates the installation of other accessories and heat dissipation for processing components;

- Verify if the motherboard has passed the corresponding safety standard tests;

- Examine the motherboard’s product packaging and supporting accessories, ensuring that all necessary items (such as various connecting cables, driver discs, and warranty cards) are complete.

Quality Inspection

Common methods for inspecting the quality of industrial motherboards include:

- Motherboard Battery Check: Inspect the battery for rust or leakage;

- Chip Production Date Verification: The performance of an industrial motherboard depends not only on the CPU speed but also on the performance of the motherboard chipset. Checking the chip production date helps assess component freshness and potential reliability;

- Software-Based Speed Testing: Use specialized software to evaluate the motherboard’s performance. Recommended speed-testing software includes products from the SPEED series and SST series.

Upgrade and Expansion Capability

When purchasing an industrial motherboard, it is essential to consider the future upgrade and expansion capabilities of both the industrial computer and the motherboard—such as the ability to expand memory, add expansion cards, and upgrade the CPU. Generally, the more slots a motherboard has, the stronger its expansion capability; however, this usually corresponds to a higher price.

As the core component of an industrial computer, the stability, reliability, and quality of an industrial motherboard directly affect the success of the entire project. Choosing a suitable industrial motherboard solution is therefore a crucial consideration.

The rapid development of industrial automation, the Internet of Things (IoT), and smart manufacturing has driven huge demand for product solutions across various industries. While design entities hold advantages in system integration, platform construction, and application layers, they face significant challenges in the current environment—where product development cycles are increasingly shortened—due to a lack of accumulated expertise and experience in segmented terminal device technologies. To address this, Xinmai Technology has launched client-oriented hardware design services and EMC (Electromagnetic Compatibility) value-added services. These services aim to accurately address the pain points in clients’ product development processes, assist with product design and certification, reduce clients’ R&D cycles, and accelerate the launch of clients’ products into the market.