Core Applications and Value of Industrial Motherboards in Industrial Control and Automation

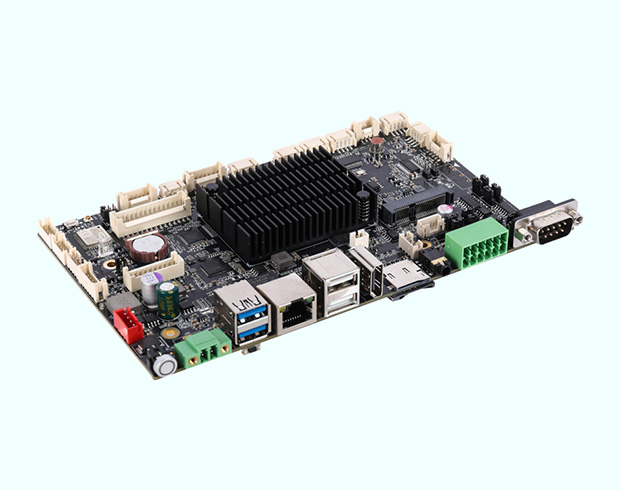

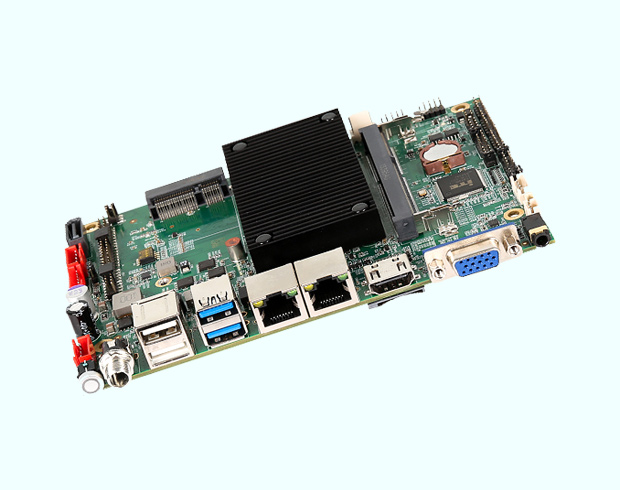

As the core hardware carrier of industrial control and automation systems, industrial motherboards, with their high stability, strong expandability, and ability to adapt to harsh environments, are gradually becoming a key hub connecting industrial on-site equipment, data, and the cloud. They are widely applied in core scenarios such as PLC replacement, equipment networked control, and production line data collection, providing solid hardware support for industrial digital and intelligent transformation.

I. Flexibly Replace Traditional PLCs, Enabling Customized Control Solutions

While traditional PLCs (Programmable Logic Controllers) excel in standardized, small-scale control scenarios, they face pain points such as insufficient flexibility in program development and limited expansion interfaces when dealing with complex, customized industrial control needs.

Based on x86 or ARM architectures, industrial motherboards can run embedded operating systems like Linux and Windows Embedded. By integrating professional control software (e.g., Codesys, LabVIEW), they achieve comprehensive replacement and upgrading of PLC functions:

- Flexible Expansion of Control Logic: Support users to write custom control programs according to production line requirements, adapt to the collaborative control of various types of executive components (motors, cylinders, sensors), and meet the customization needs of non-standard automation equipment.

- Strong Interface Compatibility: Integrate rich industrial bus interfaces (RS-232/485, CAN, EtherCAT, Profinet), enabling direct connection to various on-site industrial equipment without additional adapter modules, thus reducing system integration costs.

- Multi-Task Parallel Processing: Compared with the single-task execution mode of traditional PLCs, industrial motherboards can simultaneously handle multiple tasks such as control commands, data collection, and equipment communication, improving system response efficiency.

II. Build Equipment Networked Control Hubs, Unblock Industrial Data Links

Under the trend of Industry 4.0 and smart manufacturing, equipment networking and remote management have become core needs for improving production efficiency. Industrial motherboards play a key role as “networked control hubs” in this scenario:

- Achieve Equipment Interconnection: Through communication modules such as 5G/4G, Ethernet, and WiFi, connect scattered production line equipment (e.g., machine tools, robots, testing instruments) to industrial Internet platforms, breaking “information silos.”

- Support Remote Monitoring and Debugging: Technicians can remotely access industrial motherboards through cloud platforms to real-time monitor equipment operating status, modify control parameters, and troubleshoot faults, reducing on-site maintenance costs. This is particularly suitable for multi-plant and cross-regional production scenarios.

- Edge Computing Capabilities: Industrial motherboards with edge computing capabilities can complete local data preprocessing, logical judgment, and command issuance, reducing cloud data transmission pressure, ensuring the real-time performance of control commands, and avoiding the impact of network fluctuations on production.

III. Undertake Production Line Data Collection, Lay a Foundation for Smart Manufacturing

Industrial control and automation scenarios are often accompanied by harsh conditions such as high temperature, high humidity, strong electromagnetic interference, and excessive dust. The industrial-grade design of industrial motherboards enables stable operation in such environments:

- Wide Temperature Operating Range: Support operation from -20℃ to 70℃, adapting to high-temperature, low-temperature scenarios such as metallurgy, chemical industry, and outdoor equipment without additional temperature control devices.

- Anti-Interference and Shock Resistance: Certified by EMC (Electromagnetic Compatibility), they possess anti-static and anti-electromagnetic interference capabilities. The reinforced design can resist vibration and impact on industrial sites, meeting 24/7 uninterrupted operation requirements.

- High Reliability Design: Adopt industrial-grade components, moisture-proof and dust-proof coatings, and redundant power supply design. Their Mean Time Between Failures (MTBF) is much higher than that of commercial motherboards, significantly reducing equipment downtime risks.

With their flexibility, expandability, and industrial-grade stability, industrial motherboards are reshaping the hardware landscape of industrial control and automation. They can not only replace traditional PLCs to complete basic control tasks but also build a complete link from “equipment control” to “data intelligence” for industrial enterprises through networking, data collection, and edge computing capabilities, serving as a core hardware engine empowering the transformation towards smart manufacturing.